3D printing is generally utilized in industry and organizations these days—architecture, for example—and it is additionally quickly turning into a famous diversion for specialists. Miniatures, similar to puppets, or unique chess pieces, and outfits and adornments for cosplay are a typical road of investigation for 3D printing aficionados, with endless creators—star and novice—printing and selling their manifestations on their eBay or Etsy store. The absolute best 3d printer under 500 is isolated into classifications like a most moderate 3D printer, best 3D printer unit, quickest 3D printer, best double extruder 3D printer under $500.

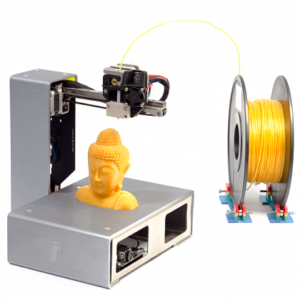

3D Printing Filament

3D printing fiber is the thermoplastic feedstock for combined statements demonstrating 3D printers. There are numerous sorts of fiber accessible with various properties, requiring various temperatures to print. The fiber is ordinarily accessible in the two standard distances across 1.75 mm and 2.85 mm. 2.85 mm fiber is now and then incorrectly alluded to as “3 mm”, yet ought not to be mistaken for the more uncommon fiber size that gauges 3 mm in distance across.

Fiber size ought not to be mistaken for the spout size, and a few unique mixes of spout and fiber sizes might be utilized. Perhaps the most well-known spout size is 0.4 mm, while instances of other normal sizes incorporate 0.35 mm and 0.25 mm. Separated from powder and fluid sap for other 3D printing innovations, the fiber is created into one consistent thin plastic string in hundred meters in length, which is normally spooled into a reel for reason for capacity and printer taking care of.

Economically delivered fiber

Heaps of industrially delivered fiber have been contracted to shield the fiber from dampness. 3D printing fiber is made utilizing a cycle of warming, expelling, and cooling plastic to change nurdles into the completed item. In contrast to a 3D printer, the fiber is obtained as opposed to pushing through the spout to make the fiber, the distance across the fiber is characterized by the interaction that happens after the plastic has been warmed instead of the measurement of the extruder spout. An alternate power and speed are applied to the fiber as it is pulled out of the extruder to characterize the width of the fiber, most normally 1.75 mm or 2.85 mm breadth.

The plastic nurdles are consistently white or clear. Shades of different added substances are added to the material before it is dissolved to make hued fiber or fiber with unique properties, for example, expanded strength of attractive properties. Before the fiber is expelled the nurdles are warmed to 80°C to dry it and diminish water content. The nurdles should be dried as numerous thermoplastics are hygroscopic and expulsion of soggy plastic causes dimensional blemishes (this is likewise the situation when the completed fiber is being printed). From that point, the nurdles are taken care of into a solitary screw extruder where it is warmed and expelled into a fiber. The breadth is regularly estimated by a laser as a component of a quality control instrument to guarantee the right measurement of the fiber. The fiber is then taken care of through a warm water tank which cools the fiber which gives the fiber its round shape. The fiber is then taken care of through a virus water tank to cool it to room temperature. It is then injured onto a spool to make the completed item.